- Cable wire Coiling Binding

- Tape winding machine

- Semi-auto strip twist brush

- Wire cutting stripping machine

- Semi-auto crimping machine

- Stripper crimper Blades

- Terminal Tensile Tester

- Cut-off machine

- Cable labeling machine

- Strapping banding tool

- Terminals/connector/Plugs

- Automated Tape Dispenser

- Automatic Crimp Machine

- Terminal Crimping tools

- Auto Wire feeder

- Automatic soldering machine

- Nylon Cable Tie Machine

- Injection molding machine

- Brazing welding machine

- Screw fastening machine

- Power cord crimping machine

- Wire harness tester

- Glue Dispensing Robot

- Wiring harness Packing materials

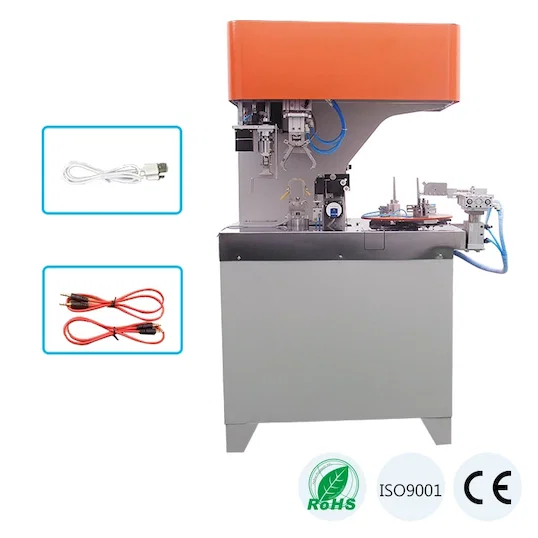

Home > Cable Wire Coiling Binding > Auto Coiling Tying Machine > Automatic Cable Winding Binding Machine For Cable Power Cord, DC Cable WPM-81M

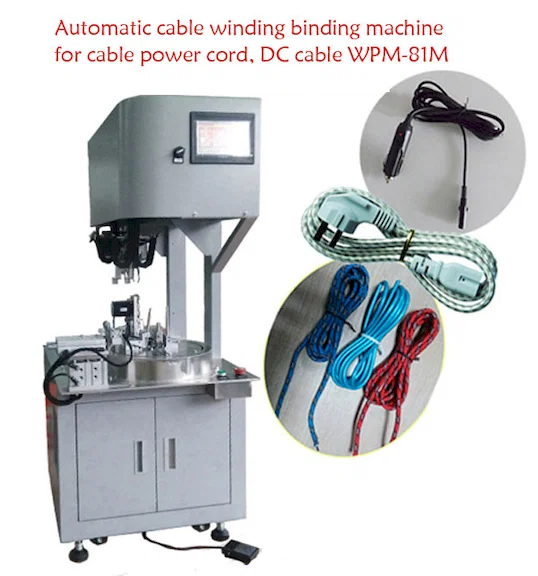

Automatic cable winding binding machine for cable power cord, DC cable WPM-81M

- Model No: WPM-81M

- WPM-81M is an automatic cable winding and binding machine designed for power cords and DC cables.

cable winding binding machine, cutting winding and tying machine, Cable Bunching Machine, Cable Coiling Tying Machine, Cable Cutting Winding Binding MachineCable winding binding machine, cutting and winding tying machine, cable bunching machine, cable coiling tying machine, and cable cutting winding binding machine.

Applicable to AC/DC/USB cable winding appearance in the 8-word single strap

Wire length 6 m or less for wire diameter Φ 6.2 mm or less

Voltage requirement: 210-240V 5A

Wind spacing: 70-200mm

Machine power ≤2000W

bundle diameter ≤ 55mm

The length of the head is 0-130 mm and the length of the tail is >0 mm

Production efficiency: 1800PCS /hour (winding 3 times with line length of 1 meter and outcrop tail) - Inquiry now

Detailed description

The 8-word single tie type is a revolutionary invention in the field of wire-tying machines. With its automatic winding capabilities, the WPM-81M cable winding binding machine has become an indispensable tool for professionals who require precision and efficiency in their work.

This cutting-edge machine not only winds wires with ease but also ties them securely, ensuring that your cables are always neatly organized and free from tangles. Its cable bunching feature allows you to group multiple wires together, making it easier to manage complex wiring systems.

The Cable Coiling Tying Machine takes things one step further by coiling your cables into neat bundles before tying them off. This saves time and effort while also reducing the risk of damage to your cables during transport or storage.

And if you need even more versatility, the Cable Cutting Winding Binding Machine can handle all three tasks at once – cutting, winding, and tying – giving you complete control over every aspect of your cable management process.

So whether you're working on a large-scale project or just need to tidy up some loose ends around the office, these innovative machines are sure to make your life easier and more efficient. Invest in one today and experience the difference for yourself!

Technical parameters:

Applicable to AC/DC/USB cable winding appearance in the 8-word single strap

Wire length 6 m or less for wire diameter Φ 6.2 mm or less

Voltage requirement: 210-240V 5A

Wind spacing: 70-200mm

Machine power ≤2000W

bundle diameter ≤ 55mm

The length of the head is 0-130 mm and the length of the tail is >0 mm

Production efficiency: 1800PCS /hour (winding 3 times with line length of 1 meter and outcrop tail)

The pressure requirement is 0.55-0.65mpa. I

t is suitable for the rubber band core

With air volume ordinary peeling machine with air volume strap weight ≤ 2.5kg

The machine size is about 850L*630W*1480H mm and the winding speed can be adjusted

The weight of the machine is about 130KG

Main parts of WPM-81m full-automatic winding tying machine with a medium 8-character single tie

Cylinder: Yadeke cylinder and solenoid valve,

Winding motor: servo motor 1000W Dongling

Take line translation motor: closed hybrid servo motor 850W lightning race

Belt conveyor motor: Stepper motor thunder race

Torsion strap motor: Stepper motor thunder race

PLC: Fengwei screen: maintenance control

Rack: Iron rack power supply: clear weft

Wire claw/twist claw/lower claw material: stainless steel

Drive system: high-reliability servo system, a control system for high-speed stable industrial grade controller and system software, English and Chinese bilingual edition.

WPM-81m full-automatic winding wire tying machine with a medium 8-character single tie

1. The new style with a middle matching shape is wrapped around figure 8 and tied with a tie belt;

2, suitable for USB/DC/AC cable, can leave the head and tail, head and tail, head and tail;

3. The winding motor adopts a 1000W servo, full of power and more stable;

4. The line-taking translation motor is mixed with an 850W servo to prevent the stepping phenomenon and demagnetization of the stepping motor, and the translation is more stable;

5. The bearing capacity of the tie belt can be up to 2.5kg, which reduces the frequency of changing the tie belt and improves the working efficiency;

6. The production efficiency can reach 1800 pieces/hour, saving labor;

7. Easy to operate, debug and maintain;

8. Small size, not taking up space, saving rent;

9. Humanized design can reduce the fatigue strength of employees;

10. Programmable controller (PLC) control, double-version man-machine interface control in Both Chinese and English

The 8-word single tie type is a revolutionary invention in the field of wire-tying machines. With its automatic winding capabilities, the WPM-81M cable winding binding machine has become an indispensable tool for professionals who require precision and efficiency in their work.

This cutting-edge machine not only winds wires with ease but also ties them securely, ensuring that your cables are always neatly organized and free from tangles. Its cable bunching feature allows you to group multiple wires together, making it easier to manage complex wiring systems.

The Cable Coiling Tying Machine takes things one step further by coiling your cables into neat bundles before tying them off. This saves time and effort while also reducing the risk of damage to your cables during transport or storage.

And if you need even more versatility, the Cable Cutting Winding Binding Machine can handle all three tasks at once – cutting, winding, and tying – giving you complete control over every aspect of your cable management process.

So whether you're working on a large-scale project or just need to tidy up some loose ends around the office, these innovative machines are sure to make your life easier and more efficient. Invest in one today and experience the difference for yourself!

Technical parameters:

Applicable to AC/DC/USB cable winding appearance in the 8-word single strap

Wire length 6 m or less for wire diameter Φ 6.2 mm or less

Voltage requirement: 210-240V 5A

Wind spacing: 70-200mm

Machine power ≤2000W

bundle diameter ≤ 55mm

The length of the head is 0-130 mm and the length of the tail is >0 mm

Production efficiency: 1800PCS /hour (winding 3 times with line length of 1 meter and outcrop tail)

The pressure requirement is 0.55-0.65mpa. I

t is suitable for the rubber band core

With air volume ordinary peeling machine with air volume strap weight ≤ 2.5kg

The machine size is about 850L*630W*1480H mm and the winding speed can be adjusted

The weight of the machine is about 130KG

Main parts of WPM-81m full-automatic winding tying machine with a medium 8-character single tie

Cylinder: Yadeke cylinder and solenoid valve,

Winding motor: servo motor 1000W Dongling

Take line translation motor: closed hybrid servo motor 850W lightning race

Belt conveyor motor: Stepper motor thunder race

Torsion strap motor: Stepper motor thunder race

PLC: Fengwei screen: maintenance control

Rack: Iron rack power supply: clear weft

Wire claw/twist claw/lower claw material: stainless steel

Drive system: high-reliability servo system, a control system for high-speed stable industrial grade controller and system software, English and Chinese bilingual edition.

WPM-81m full-automatic winding wire tying machine with a medium 8-character single tie

1. The new style with a middle matching shape is wrapped around figure 8 and tied with a tie belt;

2, suitable for USB/DC/AC cable, can leave the head and tail, head and tail, head and tail;

3. The winding motor adopts a 1000W servo, full of power and more stable;

4. The line-taking translation motor is mixed with an 850W servo to prevent the stepping phenomenon and demagnetization of the stepping motor, and the translation is more stable;

5. The bearing capacity of the tie belt can be up to 2.5kg, which reduces the frequency of changing the tie belt and improves the working efficiency;

6. The production efficiency can reach 1800 pieces/hour, saving labor;

7. Easy to operate, debug and maintain;

8. Small size, not taking up space, saving rent;

9. Humanized design can reduce the fatigue strength of employees;

10. Programmable controller (PLC) control, double-version man-machine interface control in Both Chinese and English

Related products

link : cablecutting.net xmjw.ltd

- Categories

- Cable wire Coiling Binding

- Tape winding machine

- Semi-auto strip twist brush

- Wire cutting stripping machine

- Semi-auto crimping machine

- Contact Us

sales@cablecutting.net

sales@cablecutting.net kevin201166

kevin201166 +86-18965153335

+86-18965153335

- Copyright @ 2003-2023 XIAMEN JINGWEI TECHNOLOGY CO., LTD.

- E-mail sales@cablecutting.net npsales@126.com

- Contact: Mr. Kevin, Ms. Donna

- Tel:+86-0592-8628902 Mobile:+86-18965153335 Skype: kevin201166 Fax:+86-0592-6065010