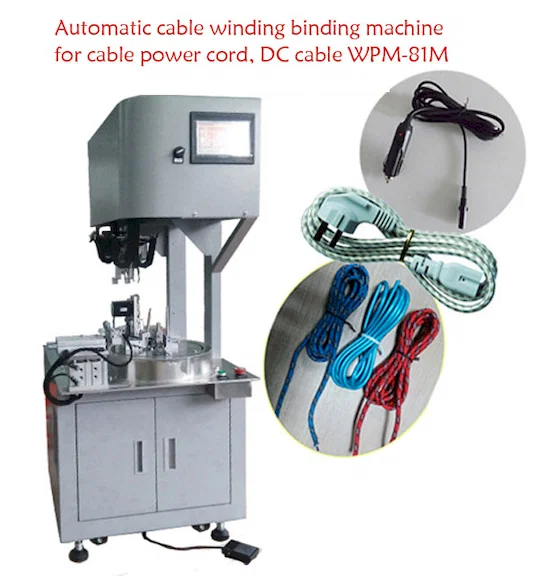

WPM-81M is an automatic cable winding and binding machine designed for power cords and DC cables.

Cable winding binding machine, cutting winding and tying machine, Cable Bunching Machine, Cable Coiling Tying Machine, Cable Cutting Winding Binding MachineCable winding binding machine, cutting and winding tying machine, cable bunching machine, cable coiling tying machine, and cable cutting winding binding machine.

Applicable to AC/DC/USB cable winding appearance in the 8-word single strap

Wire length 6 m or less for wire diameter Φ 6.2 mm or less

Voltage requirement: 210-240V 5A

Wind spacing: 70-200mm

Machine power ≤2000W

Bundle diameter ≤ 55mm

The length of the head is 0-130 mm and the length of the tail is >0 mm

Production efficiency: 1800PCS /hour (winding 3 times with line length of 1 meter and outcrop tail)