Detailed description

Solve Decades-Old Crimping Challenges with the Revolutionary Automatic Crystal Head Crimping Machine

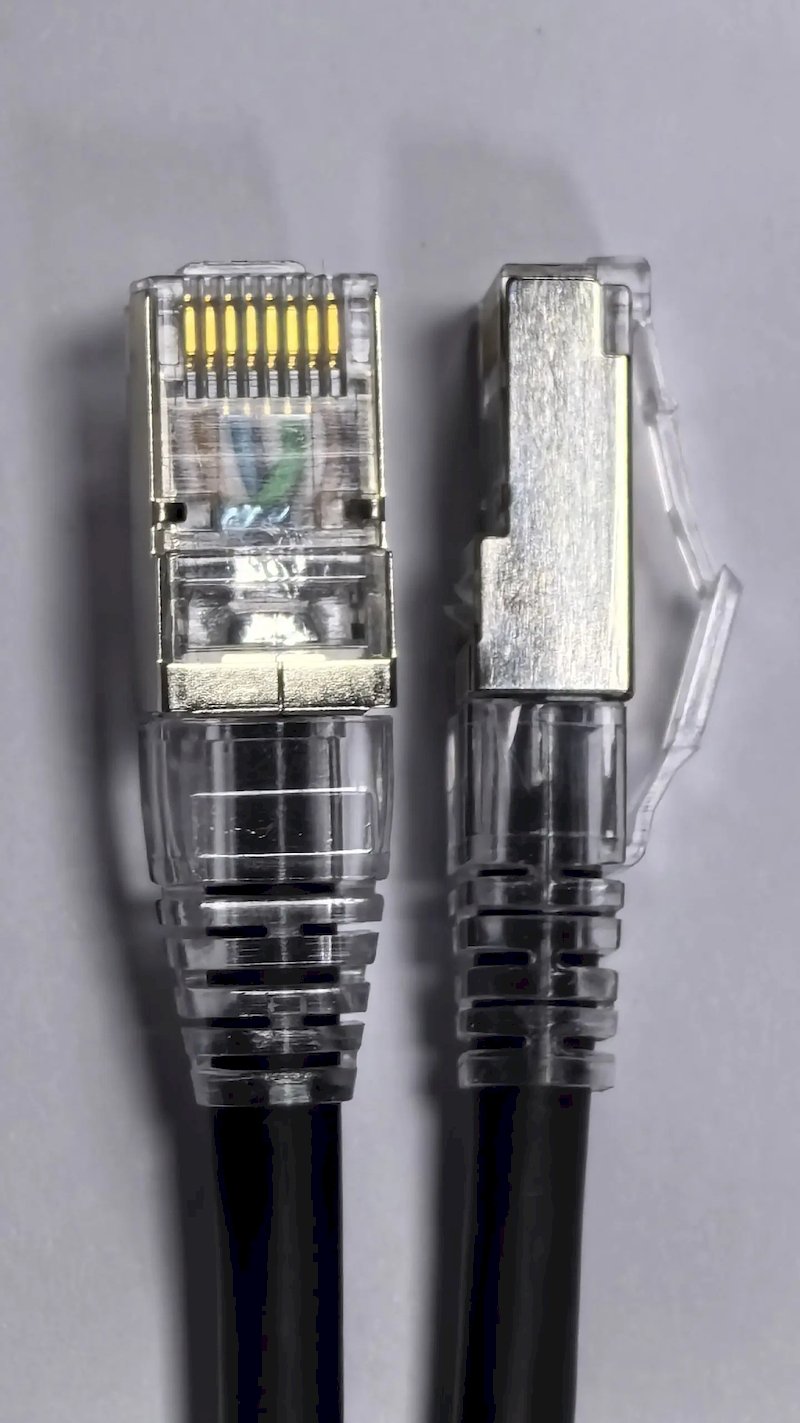

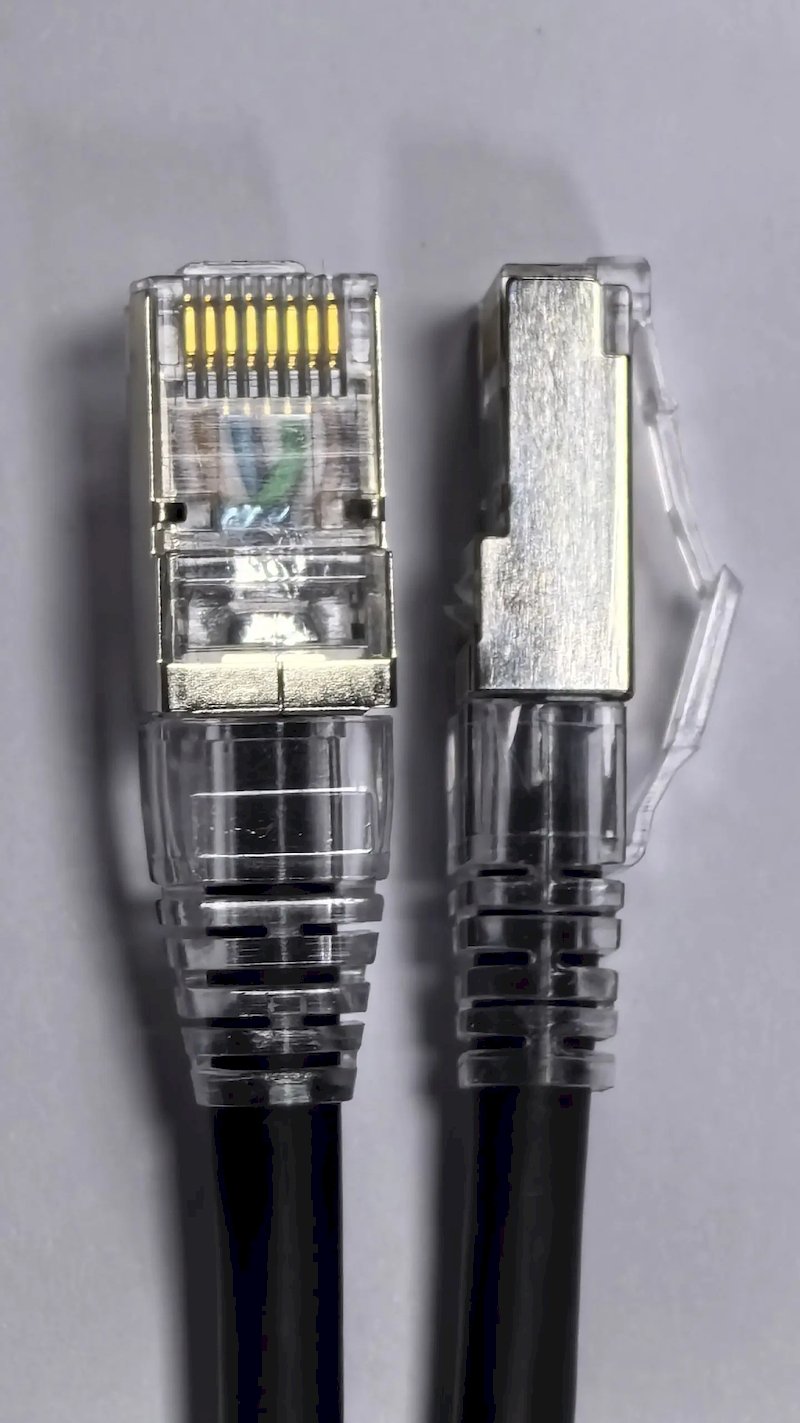

Introducing the Automatic Crystal Head Crimping Machine, model WPM-CAT6-CAT6A, a groundbreaking innovation poised to transform your cable assembly process. This world-first product directly addresses long-standing industry issues by offering a fully automated solution for crimping Crystal Heads (Two-Piece + Jacket), especially for demanding applications like Sheathed Cables.

Unleash Unprecedented Automation and Efficiency in Crystal Head Crimping

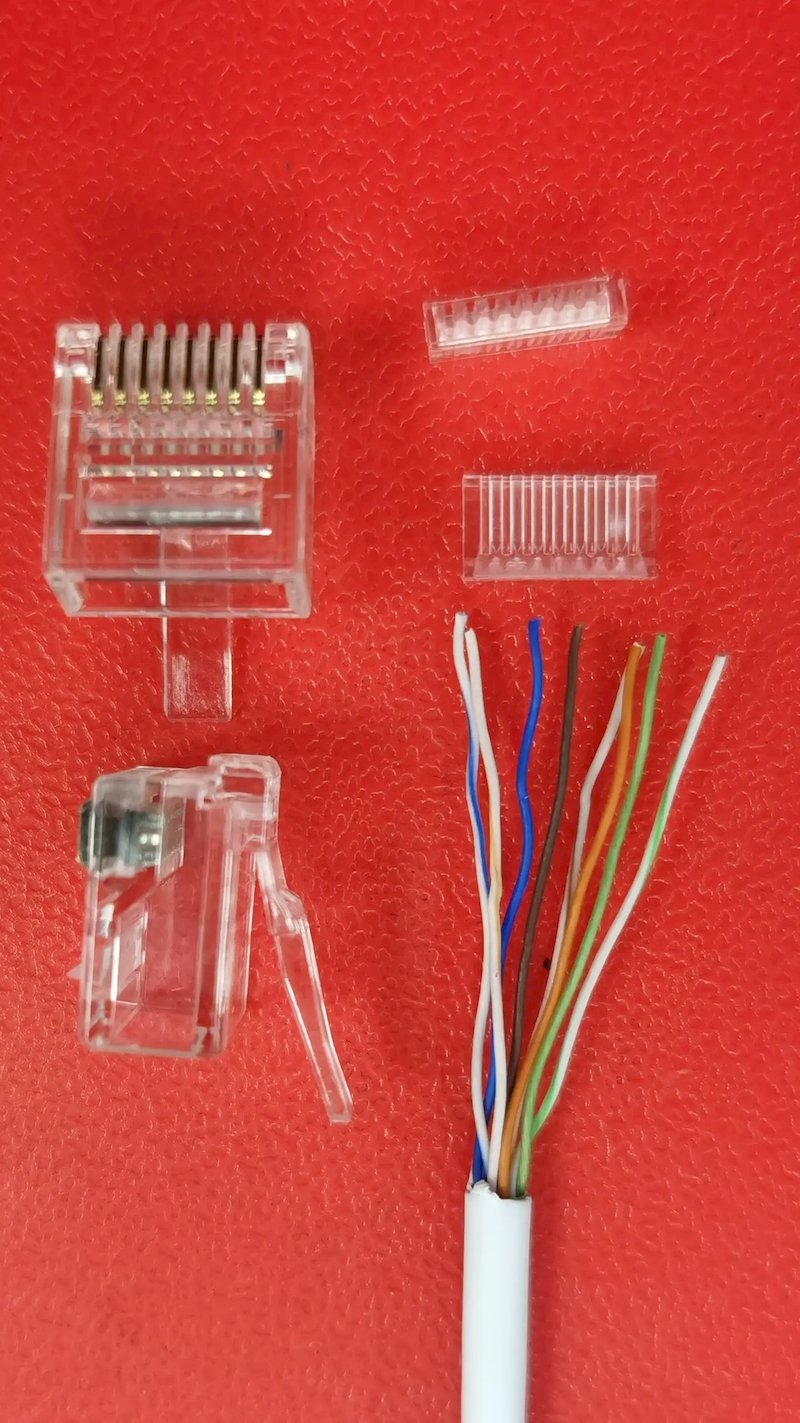

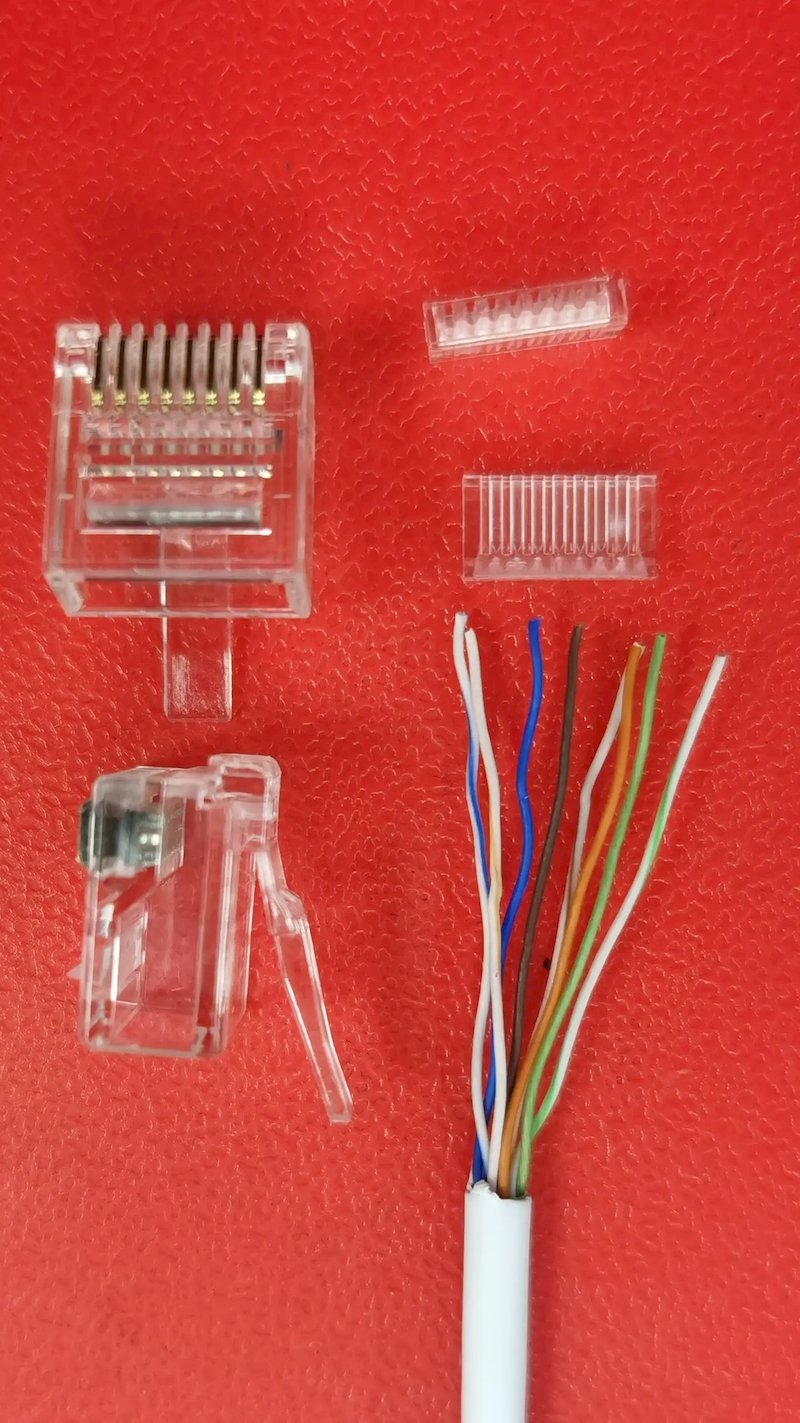

This patented Crystal Head Crimping Machine redefines user-friendliness and operational efficiency. With a simple manual feed and placement process, the WPM-CAT6-CAT6A automatically executes a series of complex operations in one seamless flow. These operations include: wire feeding, jacket feeding, cutting, re-feeding, wire clamping (using a small bracket), threading the crystal head body, threading the jacket, crimping, and finally, wire retrieval.

Imagine the labor savings – one WPM-CAT6-CAT6A machine expertly replaces 4-6 skilled wire-threading workers and completely eliminates the need for dedicated crimping operators. Currently unparalleled in the market, this Automatic Crystal Head Crimping Machine is the only automated equipment capable of consistently and efficiently crimping crystal head network cables. It is specifically designed for long-body two-piece crystal heads, single-row hole-blocking small brackets, and claw-hook jackets, eliminating the necessity for costly injection molding.

Experience Stable, Efficient, and Cost-Effective Production

The WPM-CAT6-CAT6A offers a compelling return on investment. Its stable and efficient operation, low running costs, and high production output result in rapid cost recovery within a few months. Enjoy long-term profitability and eliminate the frustrations associated with relying on a shrinking pool of skilled manual crimping labor.

Product Advantages: The WPM-CAT6-CAT6A Difference

-

PLC Touch-Screen Control: Managed by a programmable PLC with an intuitive touch-screen human-machine interface for clear data display and effortless parameter setting.

-

Foolproof Operation: Designed for ease of use, requiring no prior experience and significantly reducing training expenses.

-

High-Precision Servo Drive System: Equipped with 4 sets of high-precision, high-power servo motors and linear modules ensuring stable, reliable, and efficient performance.

-

Consistent Product Quality: Automated crimping guarantees product consistency and unparalleled quality assurance, eliminating human error.

Product Name and Model:

-

Automatic Crimping Machine for Crystal Heads, DS Series (WPM-CAT6-CAT6A)

Machine Specifications